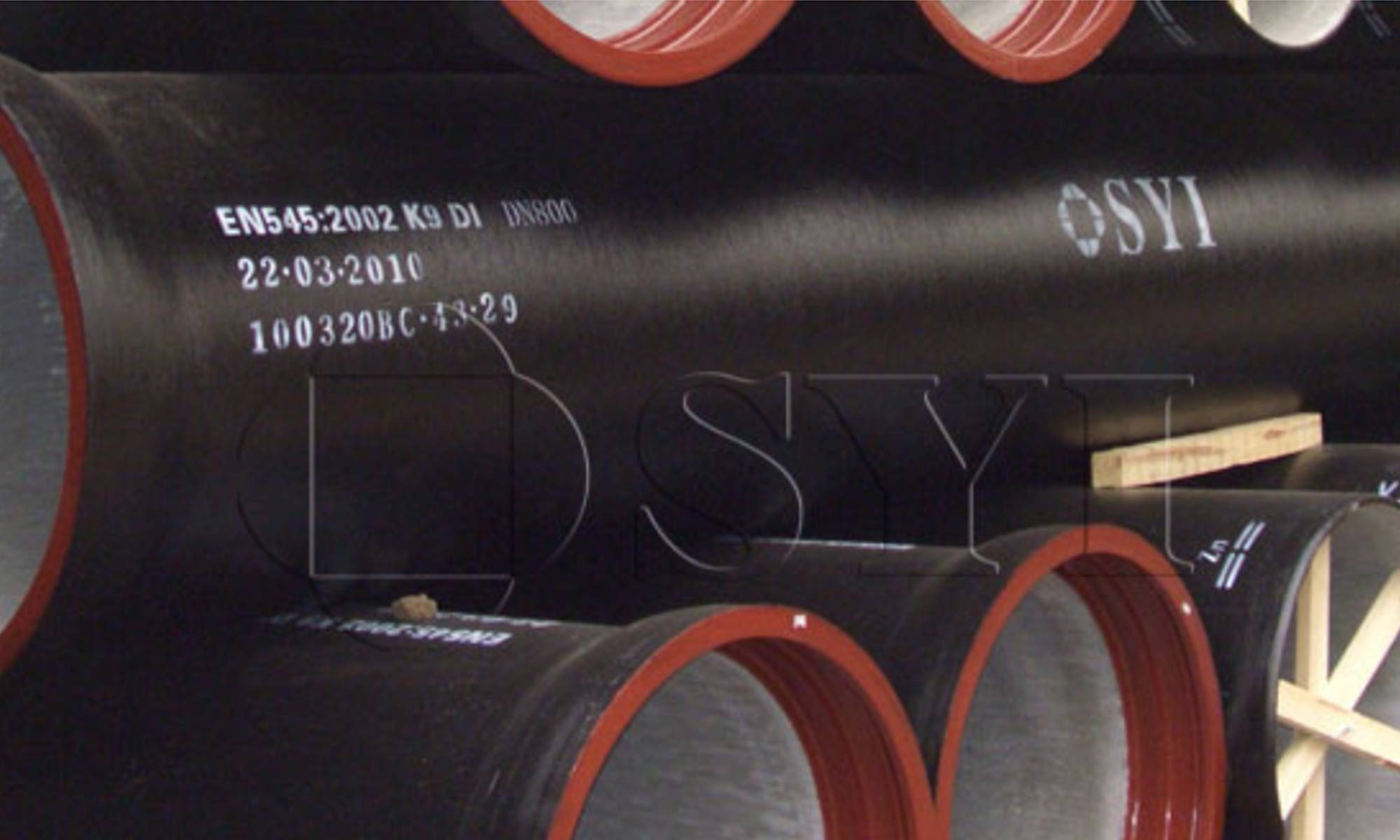

SYI Pipeline Corporation has an annual supply capacity of 150,000 tons, and it is still developing all the time. |

– According to I

|

ASSURED PERFORMANCE:

– Proof tested: Every piece of Ductile Iron Pipe must be hydrostatically tested according to standard requirements before application of lining or coating.

– Long Life: In over 1000 locations in the world cast iron mains are still in service over 100 years.

– Design: ISO/EN/AWWA/AS specifications provide a high factor of safety based on rated pressure plus surge allowance without damage to the pipes.

– Greater Carrying Capacity: Larger than nominal inside diameters of Ductile Iron Pipes provide greater carrying capacity than other pipes  of the same nominal size. Deliver more water with no increase in pumping costs. Continued high flow is assured by smooth cement mortar lining.

of the same nominal size. Deliver more water with no increase in pumping costs. Continued high flow is assured by smooth cement mortar lining.

– Easy to Field-Cut: To accurately locate fittings and connections, Ductile Iron Pipes can be easily and quickly cut at the jobsite as needed by several methods-milling cutters, abrasive wheel or cutting torch. No costly job delays waiting for factory-made special connections.

– Available to Tap: You do not need a tapping saddle for Ductile Iron Pipes. It gives strip-proof threads. Ductile Iron beats PVC/Asbestos/GRP pipes in every tapping test by cost, time, internal pressure and material strength.

– Workable to weld: As compared to cast iron, weldability is good. Flanges and paddle flanges can also be attached to Ductile Iron Pipes by welding.

– High Temperature Workability: It is largely acknowledged from many reports that Ductile Iron has better heat resistance, it is workable at a high temperature. When more fabrication processing is given to it, the post-work Ductile Iron, annealed to give it the ferrite structure, increases its elongation and impact resistance.

– Long Lengths: Fewer joints to assemble provide installation economy.

– Super Strong: Controlled combination of strength, abrasion resistance and impact resistance. Extra rugged to withstand severe stresses caused by heavy earth and truck loads, soil movements and severe service conditions.

– Super Strong: Controlled combination of strength, abrasion resistance and impact resistance. Extra rugged to withstand severe stresses caused by heavy earth and truck loads, soil movements and severe service conditions.

– Impact Resistant: Resist damages in shipping, installation and service.

– Design Flexibility: Pipes will safely function over a wide range of operating pressure, trench loads and installation conditions. Standard design includes a generous factor of safety to protect against unknowns.

– Easier Handling: Ductile Iron Pipes can be more easily manoeuvered under and around existing underground obstructions, thereby eliminating unnecessary changes in line or grade.

– Superior Joints: Easily assembled push-in joints speed job progress, minimize installation cost. Joint remains leakproof under all operating pressures.

– A complete Range: Ductile Iron Pipes are available with a complete range of fittings and accessories in sizes from 80 to 1600 mm dia. and a variety of linings and coatings for varied service conditions.

COMPARISON OF PROPERTIES:

| Item | D.I. Pipe | G.I. Pipe | Steel Pipe | PVC Pipe | Asbestos Pipe |

| Tensile Strength (N/mm²) | 420 | 150-260 | 400 | 53 | 20-23 |

| Bending Strength (N/mm²) | 590 | 200-360 | 400 | 80-100 | 20-30 |

| Elongation (%) | 10 (DN40-1000) | – | 18 | 50-150 | |

| Elasticity Coefficient (N/mm²) | Approx. 16×104 | Approx. 11×104 | Approx. 16×104 | Approx.27-30×102 | Approx.21×103 |

| HardnessHB | 230 | 230 | Approx. 140 | R 115 Rockwell | 35-40 |

| Corrosion Resistance after 90 days (g/cm²) | 0.0090 | 0.0103 | 0.0273-0.0396 | ||

| Poison’s Ration | 0.28 | 0.25 | 0.3 | 0.37 | 0.18-0.25 |

| Impact Value Kg. M/cm² | 0.713 | 0.5 | 1.5 | 0.007-0.1 | – |

| Specific Gravity | 7.15 | 7.15 | 7.85 | 1.43 | 2.1 |

| Thermal Expansion Coefficient | 1.0×10-5 | 1.0×10-5 | 1.1×10-5 | 6-8×10-5 | 0.6-0.8×10-5 |

ANGULAR DEFLECTION:

When a small curve is required along the pipeline, adjustment can be easily made without using fittings owing to the flexible joints of the pipes. So, the pipeline with flexible joints can also wind with the change of the ground.

Manufacture Processes Quality Control

Our aim is to provide all of our customers with VALUE of the products in stead of only low prices.

| For more information or asking PDF Catalogue, Please Contact us at info@syipipeline.com |

SO 2531, EN545, EN598 and other major standars.

SO 2531, EN545, EN598 and other major standars.