Loosing flanged fittings

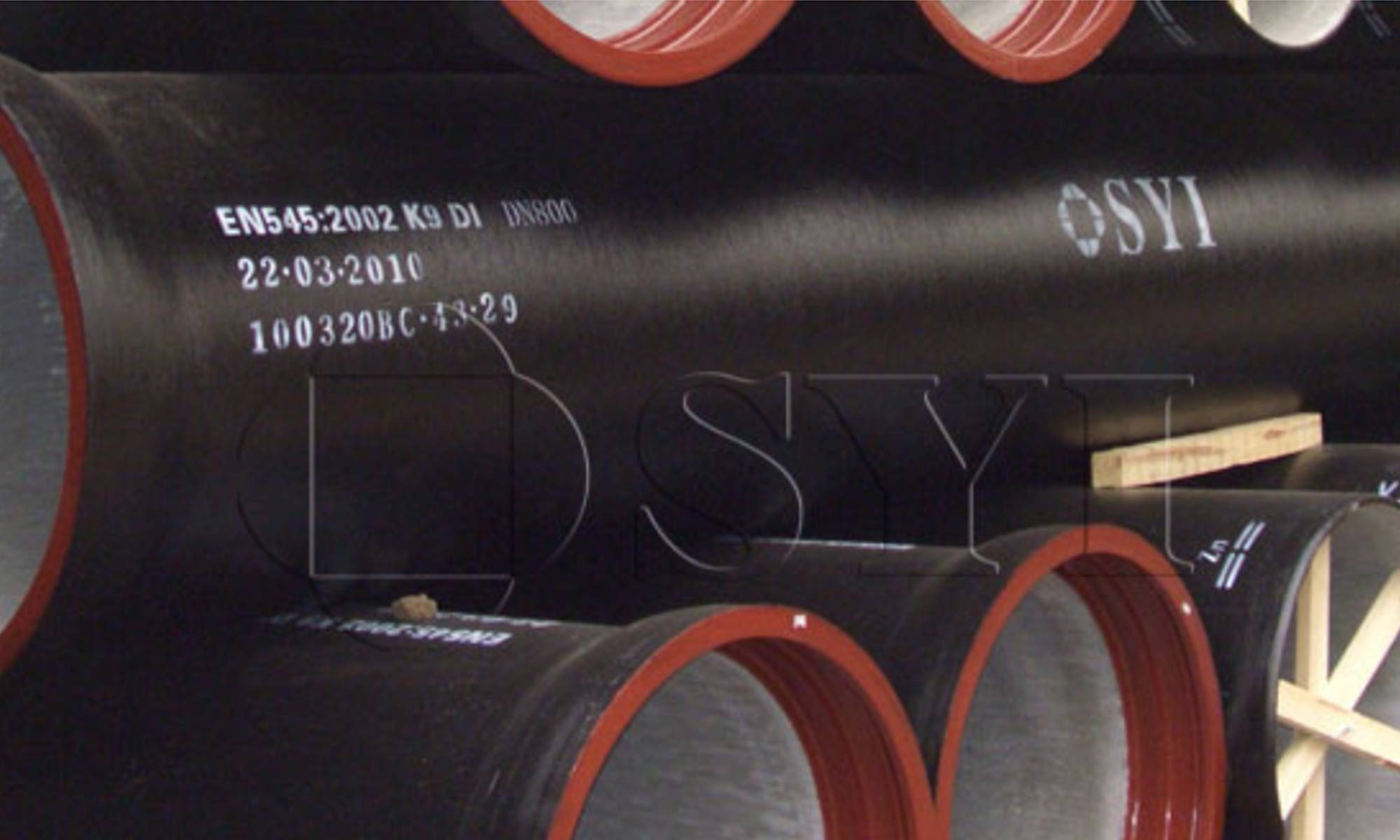

ISO2531/EN545/EN598

Flange drilling to ISO7005-2/EN1092-2

PN10/PN16

WRAS certification

Body: ductile iron Loosing flange: ductile iron

Assembled with rotatable flange, applied by FBE coated (Fusion Bonded Epoxy).

• Newly designed, less weight

• Universal connection applied to multi flanged drilling

• Loosing flange freely rotated around the pipe axis before jointing, much more convenient to install.

>> Loosing Flanged 90 Deg Bend

>> Loosing Flanged 45 Deg Bend

>> Loosing Flanged 22.5 Deg Bend

>> Loosing Flanged 11.25 Deg Bend

>> All Loosing Flanged Tee

>> Loosing Flanged Spigot